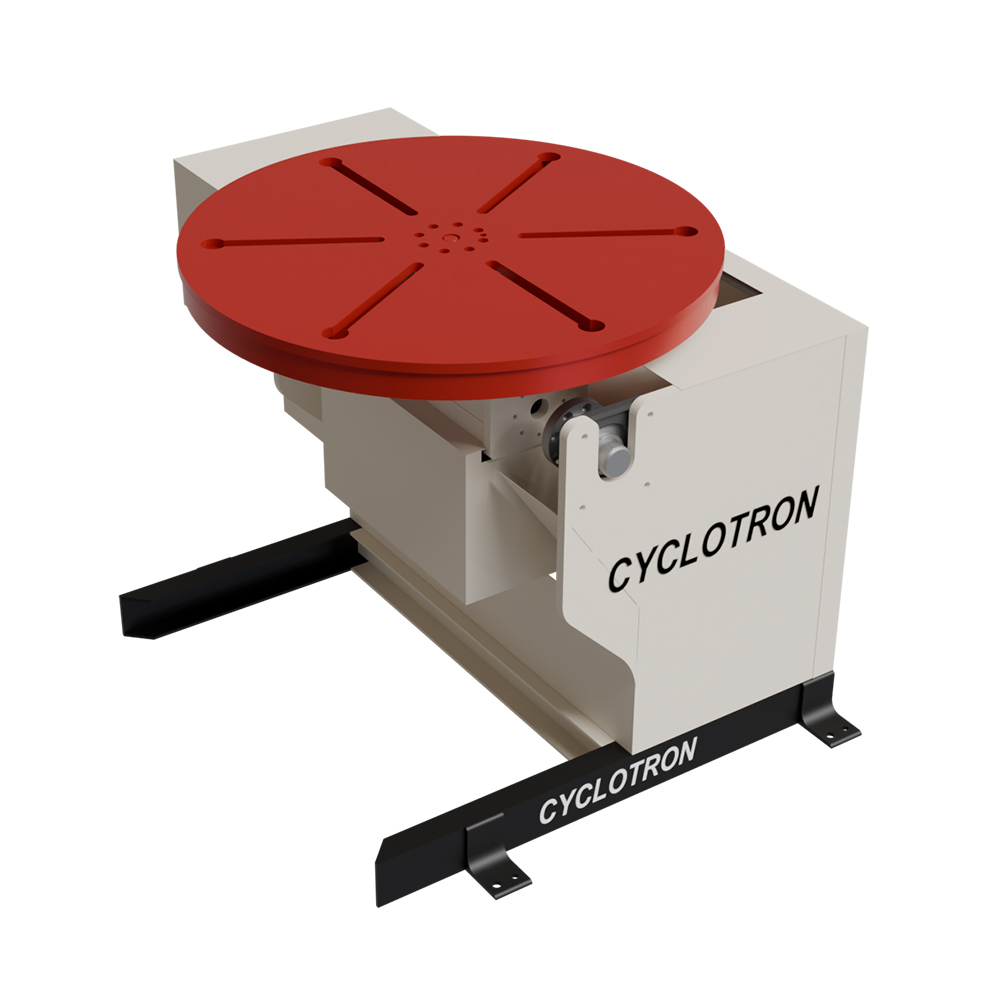

2 Axis Welding Positioner- 300 kgs

Cyclotron's

2 Axis welding positioner- 300 kgs

Cyclotron is India’s leading manufacturer of 300 kgs 2 axis welding positioner manufacturer. This positioner is suitable for manual welding in 2 directions, the face plate rotates 360 degrees and also tilts from 0-90 degrees in motion.

Cyclotron positioners are built to improve your welding performance and speed.

Technical details 300 kgs positioner

| Sr No | Description | Value |

|---|---|---|

| 1 | Load Capacity | 300 kgs |

| 2 | Application | Manual welding |

| 3 | Face plate diameter | 700 mm |

| 4 | No of slots | 6 |

| 5 | Slot size | 18 mm |

| 6 | Operating height | 725 mm |

| 7 | Face plate rotation | Motorised |

| 8 | Face plate rotation RPM | 1.0 to 1.1 |

| 9 | Face plate tilting | Motorised |

| 10 | Face plate tilting RPM | 1.0 to 1.1 |

| 11 | Face plate tilting angle | 0-100 degrees |

| 12 | Overall size (LxBxH) | 660x800x725 |

| 13 | Total weight | 225 kgs |

| 14 | Surface coating | Epoxy paint |

| 15 | Available color | Ivory |

How to choose the right 2 axis welding positioner?

-

Workpiece Size and Weight:

Ensure the positioner has the load-bearing capacity to support your heaviest components. Overloading can cause instability, motor failure, or inaccurate positioning. -

Precision and Automation Needs:

For high-precision applications or robotic welding integration, opt for electric or servo-controlled positioners. These models allow for programmable movements, variable speeds, and precise angular control.

-

Speed and Control Options:

Different welding jobs require different rotation or tilt speeds. Advanced models offer variable-speed settings and control interfaces for fine-tuned operations. -

Cost and ROI:

While higher-capacity or robotic models come with a higher price tag, they provide long-term savings through faster production, reduced rework, and less material wastage. Balance your budget with your current and future production demands.

Maintenance and Care Tips

To ensure the longevity and smooth functioning of your welding positioner, follow these best practices:

- Regular Inspection: Check for wear and tear in gears, bearings, and clamping mechanisms.

- Lubrication: Keep all moving parts properly lubricated to reduce friction and prevent premature failure.

- Cleaning: Regularly clean the positioner, especially in key mechanical and electronic components, to remove dust, spatter, and welding debris.

Training: Operators should be trained on the safe and efficient use of the equipment. Machine-specific training programs are recommended to reduce the risk of errors or damage.